ARTICLE

ARTICLE

30 JANUARY 2024

PRODUCT CARBON FOOTPRINT (PCF) 2.0,

With the upcoming reporting and disclosure requirements (IFRS/ISSB) to make Scope 3 mandatory, there is a growing momentum by large corporations to request their suppliers to report their carbon footprints. This is to enable a more accurate GHG emission measurement, i.e. using primary emission factor data, rather than using secondary emission factor data (such as EEIO for spend based method, or from LCA databases).

Why Suppliers Carbon Footprint? For most industries, scope 3.1 (Scope 3 category 1 : Purchased Goods and Services) constitutes a major portion of their Total emissions, more often than not, the highest scope 3 category. Furthermore, it is also a category which is influenceable especially by the larger corporations, in targeting for eventual decarbonisation through their procurement practices. Rather than using Emission Intensity based on Corporate Carbon Footprint for scope 1 and 2 (which is the predominant scope boundary for companies not measuring the relevant scope 3), a more appropriate data to be shared is Product Carbon Footprint (PCF), specifically, using Cradle-To-Gate scope boundary. WBCSD, through its Pathfinder Framework (PACT), provides a harmonised methodology to enable suppliers and buyers to share primary emission factor data along the value chain. Thus allowing consistency, increased accuracy and visibility to suppliers’ carbon footprint; paving the way for informed decision making as corporations continue with their journey of greening their supply chain.

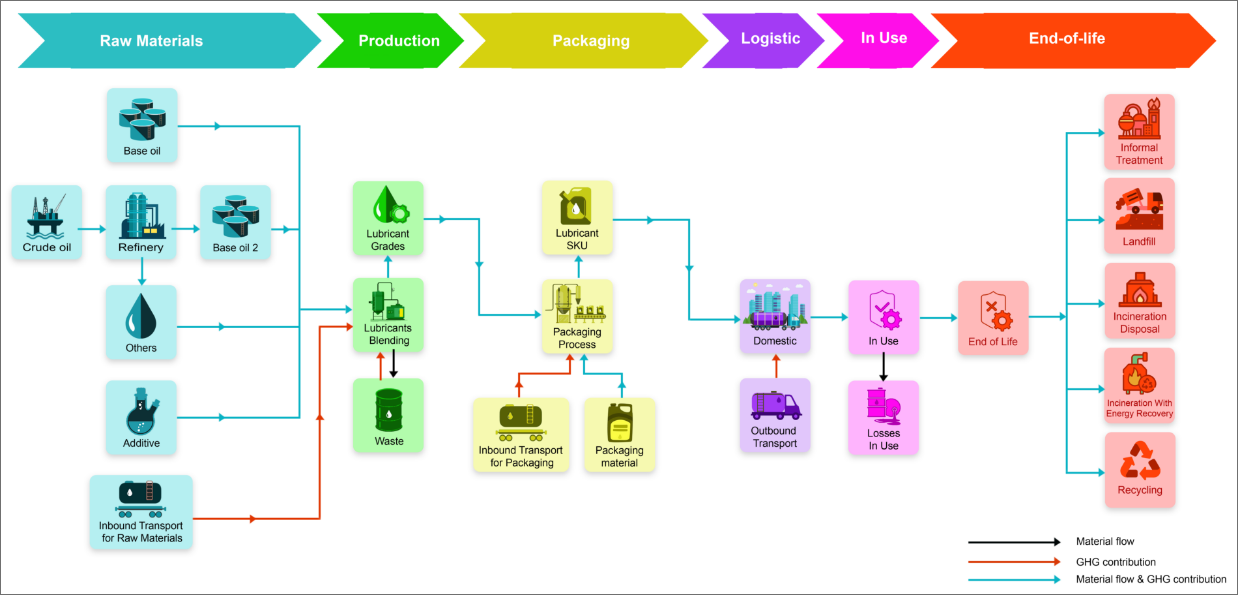

That leads to the increased need for companies to establish their PCF (as most organisations are both suppliers and customers at the same time). An example of PCF Process Map for the lubricants industry is shown, for both Cradle-to-Gate and Cradle-to-Grave Boundaries.

Figure 1 : PCF Process Map for a Generic Lubricants Company

(Screen Capture from Smart Tradzt's Enterprise PCF solution)

In the Cradle-to-Gate Life Cycle Stage components, it can be observed that some of the relevant Scope 3 categories include

- Key Raw Material (Category 1: Purchased Goods & Services)

- Inbound Logistics (Category 4: Transportation & Distribution)

- Waste Treatment (Category 5: Waste Generated in Operations)

Many factors influence the decision as to whether to use Cradle-To-Gate or Cradle-To-Grave. For example, is the PCF used for certification (where the scope boundary is predefined to enable manufacturers’ product carbon footprint comparability), product marketing differentiation (e.g. measuring avoided emission), providing Product Lifecycle carbon emission data to consumers / end buyers.

In terms of Methodology, there are various standards available to support PCF development. Cross sector Standards include ISO 14067, GHG Protocol. Industry Specific Standards are also available, e.g.

- Together for Sustainability (Chemicals)

- UEIL / ATIEL / API TR 1533 (Lubricants)

- Global Steel Climate Council (Steel)

With the advancement of digital technologies, continuous improvement in methodologies / standards and the increasing need for ecosystem partners collaboration, a new class of PCF tool with next generation capabilities: - PCF 2.0, has emerged. So, what are the examples of PCF 2.0 capabilities? To give an idea, these would include, among others

- Integration to ERP (e.g. SAP) to enable transaction level data acquisition and emissions quantification

- Support and facilitate use of Primary Emission Factor data, e.g. through value chain collaboration processes

- Conformance to the PACT framework for consistency of emission factors used

- Visibility to Data Quality using Key Performance Indicators such as

- Primary Data Share %

- Data Quality Rating

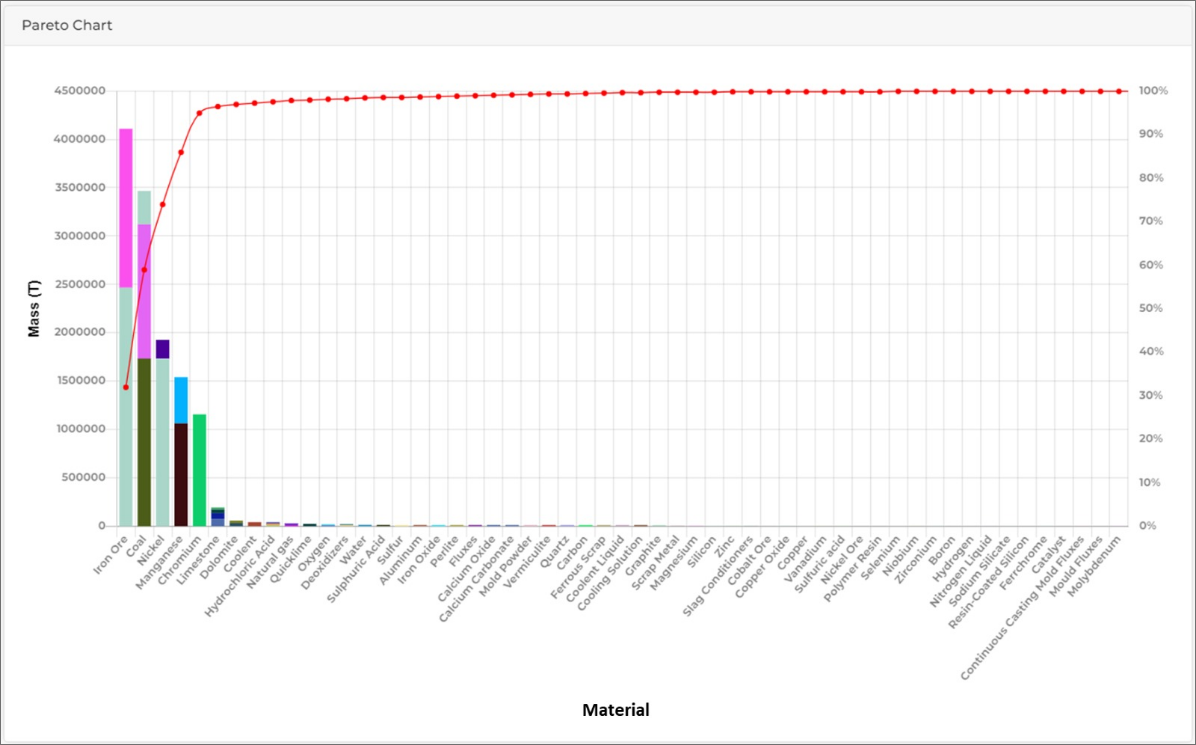

- Practical Scope 3 Tool e.g. to support determination of key raw materials to be included in scope 3.1 (as per example below); using cut off criteria e.g. at 95% total mass

Figure 2: Pareto Analysis to support implementation of PCF standards

(Screen Capture from Smart Tradzt's Enterprise PCF solution)

In summary, Scope 3 reporting and disclosure requirements have generated a driving force to get companies to start their PCF measurement. For those who are planning to update their PCF, e.g. in preparation for PACT framework conformance, perhaps it is time to consider upgrading to PCF 2.0 capability?

To find out more, please contact :

CK Chung : ck.chung@smarttradzt.com

CK Chung : ck.chung@smarttradzt.com

Osman Abu : osman.abu@smarttradzt.com

Osman Abu : osman.abu@smarttradzt.com